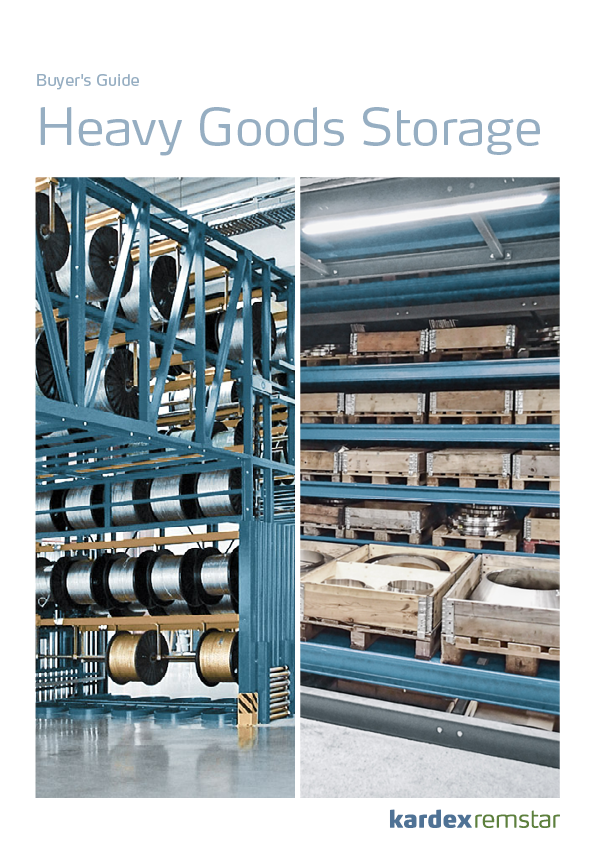

Energy / Mining Automated storage solutions for the energy and mining industry

Driven by increasing demand due to lower prices, companies working in the oil and gas and energy and mining industry need to work harder than ever before.

For manufacturers of large equipment from engines and turbines to flight simulators, printing presses, CNC machines, and sewage vacuums, intralogistics processes play a critical role. Tight drilling schedules make accessing parts and tools a critical success factor.

Warehouse challenges for manufacturing

- Storing various production components: from small parts to bulky and heavy parts

- Maintaining a continuous production flow and just-in-time supply

- Achieving high performance, excellent service, and superior quality

Warehouse challenges for on-site maintenance

- Keeping available spare parts on hand

- Having a transparent inventory overview

- Obtaining a timely reorder of critical parts

Automated storage solutions for manufacturing

Having the right parts at the right time and in the right place is critical to manufacturing operations. Kardex systems manage the storage, buffering, or supply of materials, parts, and tools. These systems provide maximum inventory availability with the lowest possible storage costs - providing parts where you need them at the exact right moment.

Whether you need to save space, manage buffer storage for semi-finished products, ensure a seamless manufacturing process, store tools within arm's reach, or pick finished items more efficiently, Kardex offers the right solution.

Customer benefits - Manufacturing

-

Storage space

High-density storage reduces warehouse footprint by up to 85%. Automated storage and retrieval systems (ASRS) maximize the vertical height in your facility to free up space.

-

Product diversity

Store materials / inventory of different sizes and weights in one storage system. Easily implement adaptations (e.g., expansions, height modifications).

-

Inventory management

The warehouse management software ensures smooth and fast material flow while giving you full transparency of all processes and inventory.

-

Security

Tools are expensive and heavy - Kardex stores them securely, with ergonomic accessibility.

-

Controlled environment

All Kardex solutions can be fitted for dry, clean, and climate-controlled environments.

Storage space

High-density storage reduces warehouse footprint by up to 85%. Automated storage and retrieval systems (ASRS) maximize the vertical height in your facility to free up space.

Product diversity

Store materials / inventory of different sizes and weights in one storage system. Easily implement adaptations (e.g., expansions, height modifications).

Inventory management

The warehouse management software ensures smooth and fast material flow while giving you full transparency of all processes and inventory.

Security

Tools are expensive and heavy - Kardex stores them securely, with ergonomic accessibility.

Controlled environment

All Kardex solutions can be fitted for dry, clean, and climate-controlled environments.

Automated storage solutions for on-site maintenance

Storing big, heavy, small, or light spare parts, retained samples, and equipment on-site on a drilling rig is challenging as space is limited. Kardex systems provide maximum storage space in minimum floor space to continuously provide you with everything you need.

When a daily supply of required material isn’t possible, you must equip your staff efficiently. This is challenging if you’re running out of space. With Kardex's space-saving solutions, you securely store a mix of spare parts and other equipment, such as work clothing, in a minimum footprint.

Customer benefits - On-site maintenance

-

Minimum storage space

Store goods of different sizes in a minimum footprint within one storage system when there is not enough space for multiple systems.

-

Permanent availability

Avoid running out of stock. Kardex's warehouse management system automatically triggers a re-order when inventory falls below a minimum required level.

-

Underground storage

Store equipment underground - Kardex will check the atmosphere (dry and salty air) and prepare the systems accordingly.

-

Speed and accuracy

Pick-to-light technology directs the operator to the exact pick location, increasing accuracy up to 99.9%.

Minimum storage space

Store goods of different sizes in a minimum footprint within one storage system when there is not enough space for multiple systems.

Permanent availability

Avoid running out of stock. Kardex's warehouse management system automatically triggers a re-order when inventory falls below a minimum required level.

Underground storage

Store equipment underground - Kardex will check the atmosphere (dry and salty air) and prepare the systems accordingly.

Speed and accuracy

Pick-to-light technology directs the operator to the exact pick location, increasing accuracy up to 99.9%.